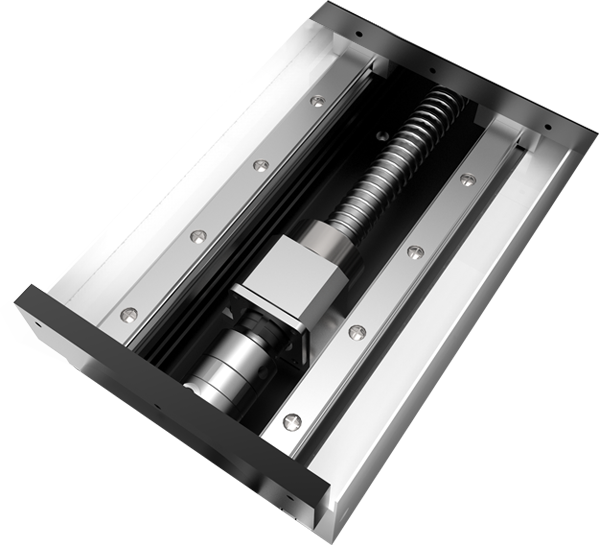

To prevent the cutting line deformation caused by the Y-axis screw bending, the Y-axis on both sides have been equipped two rails guide and double ball drive screw design to ensure the straightness and arc degree when with high-speed cutting is in operation.

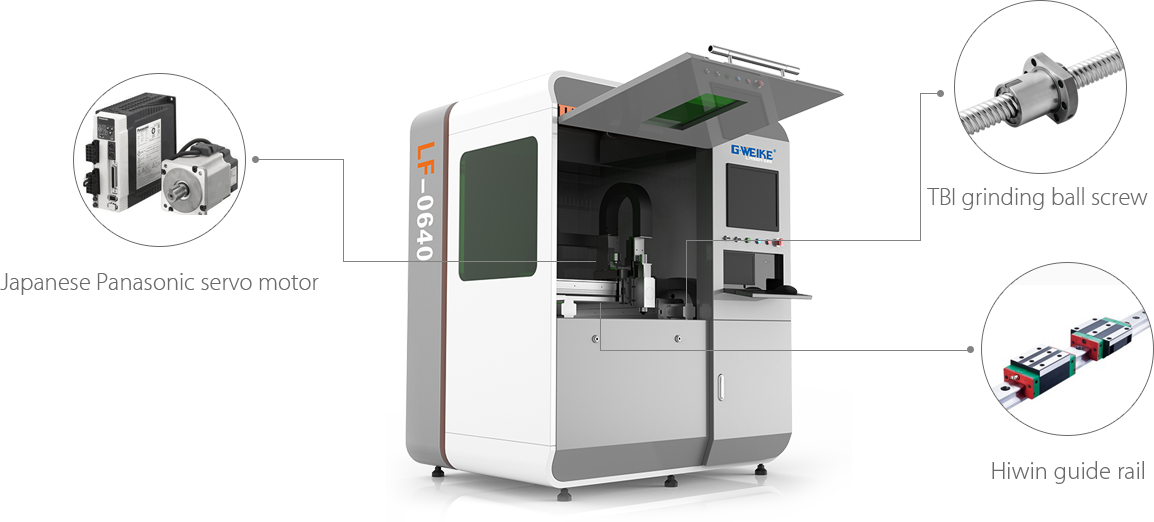

G.WEIKE fiber laser cutting machine is equipped with Japanese Panasonic servo motor, imported TBI dual driver grinding ball screw for Y axis, imported TBI grinding ball screw for X axis and Hiwin guide rail, the positioning accuracy of the machine tool can be 0.008mm and the cutting acceleration is 0.5G. The working life is more than 10 years.

| Machine model | LF0640 |

| Laser power | 500W 750W 1000W(Optional) |

| Working area | 600mmx400mm |

| Repeat positioning accuracy | ±0.008mm |

| Maximum speed | 40m/min |

| Maximum acceleration | 0.5G |

| Transmission mode | Grinding precision screw drive |

| Specified voltage and frequency | 220V/50Hz/60Hz/60A |

LF0640 is specially designed for high precision cutting. It is widely used in machinery, microelectronics, glasses, electronics and other industries,

which has high requirements on the cutting accuracy.

Professional for cutting various of thin metal sheet, stainless steel plate,

galvanized sheet, electrolytic plate and other metal materials.

Precision laser cutting machine, special for electronics, watches, glasses and other precision machinery.

MORE