Mastering Laser Welding Aluminum: The Basics

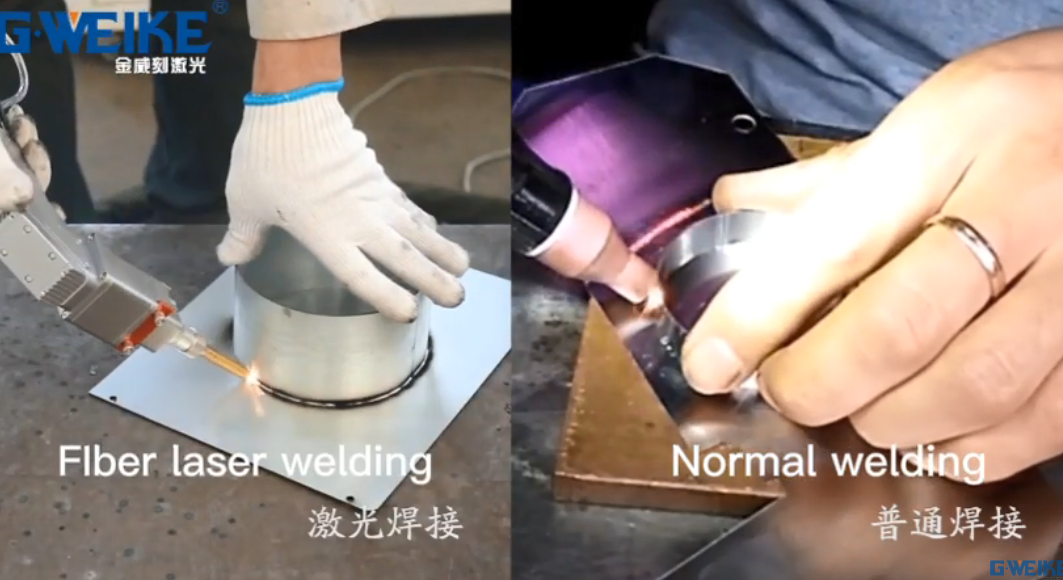

Here you will find the knowledge and skills required for laser welding aluminum and some considerations when combined with practice. Laser welding aluminum has many advantages over conventional welding, including a small heat-affected area, a strong weld and a smooth, aesthetically pleasing weld.

Aluminium has many applications and can be used in several industries, such as electrical equipment, chemical components, and window and door frames.

However, aluminum is a highly reflective and active metal prone to defects such as inclusions, porosity, and thermal cracking after welding.

How to achieve a good quality weld is a skill that many people want to understand and learn. The following are the key steps and considerations for laser welding aluminum to help you on your journey:

Types of laser sources for welding aluminium

CO2 laser source

The CO2 laser source features an output wavelength of 10.6 μm and is commonly used for welding aluminum, but it is unsuitable for welding pure aluminum.

Because aluminum has high thermal conductivity and coefficient of thermal expansion, the CO2 laser source is highly susceptible to distortion during welding. If a CO2 laser source is used for welding pure aluminum, appropriate preheating and cooling measures need to be taken to ensure the quality of the weld seam.

YAG lasers

The YAG (Yttrium Aluminium Garnet) laser source uses a YAG crystal as the laser medium and has an output wavelength of approximately 1.06 μm. It produces a higher beam quality and a smaller spot size so that a higher degree of precision and control can be achieved when welding aluminum.

The YAG laser source is more suitable for welding aluminum. If you want to weld pure aluminum or aluminum alloys, use a supplementary welding material or choose pulsed laser welding, which can achieve better welding quality.

Fiber Laser

Fiber laser welder is a new technology for welding metal materials. It has an output wavelength of 1064nm and is ideally suited to welding high-quality welds. It is the most suitable laser source for welding aluminum alloys, pure aluminum and aluminum materials.

However, the fiber laser source is expensive and unsuitable for SMALL BUSINESS and hobbyists.

The reflectivity of aluminum to three types of laser

The CO2 laser source has a reflectivity of up to 98% and can not weld pure aluminum.

| λ/μm | Aluminum |

|---|---|

| 0.7 | 77 |

| 1.06 | 80 |

| 10.6 | 98 |

Aluminium alloy classification and weldability

The following types of aluminium are common:

| Types | Ingredients | Features |

|---|---|---|

| 1000 series | Pure aluminium, low impurity content | Suitable for welding with a fiber laser source |

| 2000 series | Al - Copper | Alloys are strong and not suitable for welding. If several of these materials have to be welded, precautions need to be taken in advance to ensure good welding results. |

| 3000 series | Al-Mn | Excellent weldability |

| 4000 series | Al-Si | Commonly used as a filler material when welding other aluminium materials |

| 5000 series | Al-Mg | Cracking prone to welding when magnesium content >2% |

| 6000 series | Al-Mg-Si | Reduced strength after welding and poor formability |

| 7000 series | Al-zinc-Mg-Copper | High alloy strength, not easy to weld as it is prone to thermal cracking |

Application of laser welding aluminum

Laser welding aluminum is an emerging technology that is receiving much attention. Welding structural frames for aircraft, high-speed railways and ships use laser welder aluminum technology.

- In the transport industry: aluminum is light and strong, so it is used to manufacture engines, chassis, and wings for cars and aircraft. The laser welding of aluminum makes it possible to carry out many complex welding tasks with greater precision.

- Electronic machinery: circuit board chips are now used in smartphones, tablets, laptops, and other electronic products. Factories often use handheld laser welding machines to weld the electrical components on the top side of PCBs. It enables more precise and complex welding in smaller, delicate electronic components.

- Industrial manufacturing: door frames, window frames, and many other metal parts and machines require aluminum as a joining component, so laser welding aluminum technology, which offers high precision and efficiency, is the preferred choice. Aluminum laser welding technology also uses for aluminum kettles, pots, pans, etc.

- Renewable energy industry: Aluminium is the main material for many solar and wind power supply systems. Whether it is the production of solar panels or turbines for wind power generation, aluminum is required.

These are just a few of the common applications for laser welding aluminum. The accuracy and strength offered by laser welding aluminum make it the preferred choice for welding aluminum.

Advantages of laser welding aluminum

Laser welding aluminum has many advantages and limitations compared to conventional fusion welding. Some of the advantages of laser welding aluminum are listed below for laser welder aluminum:

Pros

- Laser weld aluminum produces aesthetically pleasing and robust welds compared to conventional fusion welding.

- Fast and productive welding of small and micro workpieces

- Small heat-affected area and narrow weld width

- Laser welding of aluminum is less prone to defects such as impurities and thermal cracks.

- The small size of the laser light plate allows for a wide range of high-precision welding.

Obstacles to aluminum laser welding

First, we all know that metal materials have different reflectivity at different wavelengths. Aluminium is a highly reflective metal with some obstacles in the welding process. If this is not done correctly, defects can easily occur, and the quality of the workpiece can be affected.

The following is a list of defects likely to occur when laser welding aluminum.

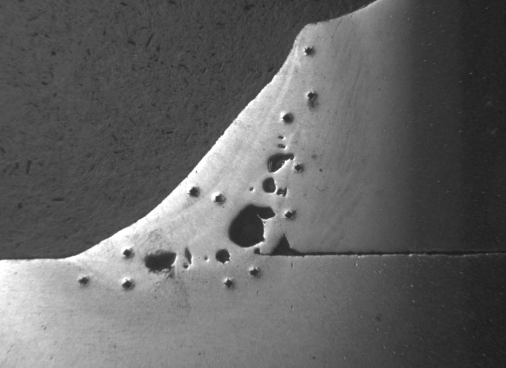

Porosity

Weld porosity is the most frequent defect in aluminum, aluminum alloys and alumina during welding. Porosity is divided into the following two main ways:

- Hydrogen holes: Hydrogen holes are common faults in welded alumina. When welding alumina, heat decomposes the water molecules in the air into hydrogen. At this point, hydrogen is very easily dissolved in the molten alumina. When the molten alumina solidifies during welding, the ability of the alumina to dissolve hydrogen drops sharply.

If the excess hydrogen does not drain smoothly to the outside of the alumina at this point, hydrogen holes will form where the hydrogen is located after solidification. - Weld holes: Weld holes are not only easily found in alumina, but are also a common welding defect in aluminum alloys. Due to the rapid cooling of the material, the gas in the molten aluminum cannot be discharged in time, resulting in many collapsed holes after cooling.

Thermal cracking

One of the other failures that Laser welding aluminum is prone to be thermal cracking, especially in the 6000 series aluminum alloys.

The magnesium and silicon in 6000 series aluminum alloys weaken the ability to form eutectic compounds, making them more susceptible to cracking.

Parameters to consider when laser welding aluminum

Laser parameters

Common laser welding is divided into pulsed and continuous lasers. The exact choice depends on the thickness of the material you want to weld.

- Pulsed lasers: Pulsed lasers are the best choice for welding industrial pure aluminum and effectively reduce the formation of porosity and thermal cracks. However, when choosing a pulsed laser, it is not easy to weld too fast and is suitable for welding thin aluminum sheets.

- Continuous laser: The laser has a stable light output, making it less prone to porosity and thermal cracking. And the surface of the weld is smoother with the continuous laser than with the pulsed laser. The weld is virtually free of weld defects and is suitable for welding thick aluminum sheets, although continuous welding is more expensive.

Power density

The power of the laser welding machine determines the welding result. If the power is too high, the weld seam is wide, and energy is wasted. If the power is low, the material cannot be adequately welded.

Beam size

For a more precise weld, choosing a laser beam between 0.2 and 2 mm is recommended.

How to reduce welding defects in laser welding aluminum

The most common welding defects in laser weld aluminum are porosity, thermal cracking, and surface collapse. Some defects can be dealt with later by fillet welding, while others can prevent others in advance. In short, controlling the rate of welding defects can be a very challenging task.

The following are some of the measures that can reasonably take to avoid welding defects:

Pre-weld treatment

Many aluminum laser welders now come with a cleaning function. You can clean the metal workpiece before welding to remove surface impurities and avoid porosity defects during welding.

Setting the right parameters

This is one of the most likely causes of welding failures. During the laser welding process, ensure the correct laser power and welding speed are set. Using inappropriate parameters can easily lead to welding faults during the welding process.

Double point welding

Double point welding is a welding process that uses two welding heads acting on the same spot, which effectively avoids porosity defects. However, this welding technique requires a high level of operator experience.

Welding with fiber laser source

The fiber laser welding machine is the most suitable laser source for welding aluminum. Welding aluminum with a fiber laser welding machine effectively avoids many welding defects. And continuous laser welding with a stable light output is ideal for aluminum welding.

Laser welding aluminum defects and solutions

| Defects | Solutions |

|---|---|

| Send Silk Katon | Check that the wire feed hose has not been bent significantly |

| Laser spot wobble | Check for short circuits in the machine's vibrating mirror motor wires |

| Blackening of weld seams | Normal blackening: 1. Insufficient gas purity 2. Welding of thin plates with a spot width of more than 3 mm |

| Insufficient depth of fusion | Increase laser power to reduce wire feed speed |

| Unsmooth surface of the weld when welding wide | Reduce welding power Reduce scanning frequency |

Conclusion

There are many challenges when laser welding aluminum and many ways to avoid welding defects to achieve higher-quality welding results.

If you want to buy an aluminum laser welder or learn more about it, please comment, and we will discuss it together.