How does a CO2 Laser Cutter Work

The CO2 laser cutter is one of the most widely used laser cutting machines available. It can engrave and cut a wide range of non-metallic materials with precision. To better understand the CO2 laser cutter, you can start by looking at the working principle.

The formation of the laser and the specific engraving principle are very complex. It cannot be easy to understand if you are not a professional. This article will give you a better understanding of how the CO2 laser cutter works in an easy-to-understand way.

How the CO2 laser cutter works

I'll talk about the components of the CO2 laser cutter and how they are used. This will make it easier for you to understand how it works.

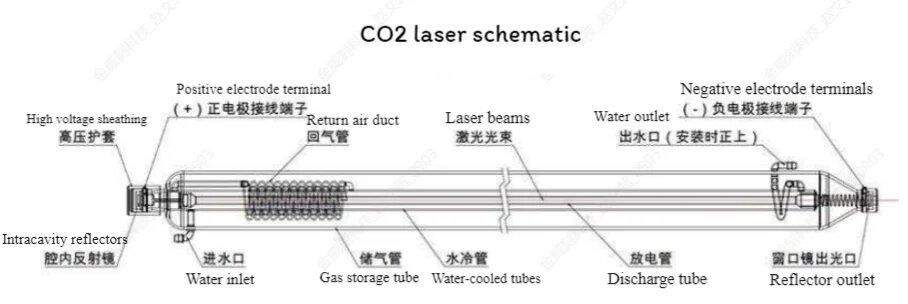

CO2 laser tube

The CO2 laser tube is the main working part of the CO2 laser cutter.

The laser tube consists of a discharge tube, a water cooling tube, a gas return tube, and a gas storage tube.

The discharge tube is filled with a mixture of gases and its length determines the laser output power. The longer the discharge point, the higher the laser power of the CO2 laser cutter.

The main function of the water-cooled tube is to cool the gas and extend the life of the laser tube. It also maintains a stable power output and prevents the discharge tube from blowing up due to heat during the working process.

The function of the return tube is to connect the two electrodes in the discharge tube. The thin spiral structure of the return tube improves the unbalanced voltage distribution between the two electrodes. It also helps block the discharge effect between the gas reservoir and the electrodes, ensuring that the discharge occurs only in the discharge tube.

The gas storage tube increases the gas storage capacity of the gaining medium, reducing changes in the composition and pressure of the working gas during the discharge process and extending the service life. And the gas storage tube enhances the mechanical strength and stability of the discharge tube.

The service life of the laser tube is closely related to the gas content of the tube, and if the gas leaks or decreases to a certain level, it needs to be replaced with a new laser tube. There is no way to replenish the gas in the laser tube from outside.

Optics

The optics in the CO2 laser cutter combine the laser beams produced by the laser tube and direct them in the required direction. The light ions are reflected back and forth in the laser tube, increasing in intensity. When the energy is strong enough, some light ions can be directed to the lower two reflectors through the laser tube by the exit reflector.

The entire optical path has three reflectors, and as a result of the constant convergence, the diameter of the laser beam increases from 7 mm at the beginning to only 0.1-0.7 mm at the end, and the intensity of the laser beam increases during this process.

Laser head

The high-intensity laser beam passes through the laser head's focusing mirror, moving quickly around the machine with amazing cutting power and speed.

Advantages of the CO2 laser cutter

The advantages of the Co2 laser cutter are numerous. The common working medium is homogeneous, the construction is simple and easy to operate and it can work continuously for a long time. The laser beam has a high cutting efficiency and a good cutting effect. At the same time, the Co2 laser cutter is available at a low price, making it suitable for many small businesses.

It is mainly used for cutting and engraving non-metallic materials such as wood, acrylic, density board, fabric, marble, glass, etc. It is widely used in the textile and material processing industries and the medical sector.

- Non-contact cutting: The laser beam does not come into contact with the material during the cutting process, so there is no material wear and tear on the machine during the entire cutting process.

- Safety: Both industrial and desktop Co2 laser cutters are equipped with professional laser protection housing and the machines are equipped with numerous safety features. The machines are computer-controlled and do not require manual operation, so they are safer to use than conventional cutting.

- High precision: The Co2 laser cutter can cut to an accuracy of 0.01mm.